Planters..!!!

Let's explore more about uses of composite concrete..

We will discuss more in our next blog.. meanwhile let me know whats in your mind about this blog..

Best Regards,

Dave

Let's explore more about uses of composite concrete..

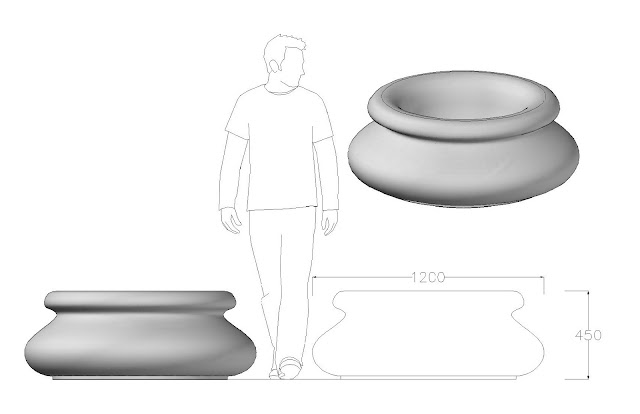

One of the most widely used product fall in the category of landscape articles - Planter. Below is the example of low bowl planter. As we have seen in our previous blog on concrete furniture, this bowl planter is made of pigmented concrete (colored concrete). The color was developed using green and yellow iron oxide. 3D curve surface was created using light weight fiberglass mold.

|

| Low Bowl Concrete Planter |

Sealed concrete surface added gloss to its final look, but high gloss effect was only possible with polishing application. Below is the sketch of the low bowl planter. The product is about 4ft wide and 1.5 ft tall. It weights only 100 KG as its hollow from inside.

|

| Sketch of Low Bowl Planter |

We have tried to float this planter in the water tank at site and it was really floating on water..!!! You are thinking in right direction, you may design a floating garden on lake or any other stable water body..!! Remember to seal inner surface before you float this planter.

We will discuss more in our next blog.. meanwhile let me know whats in your mind about this blog..

Best Regards,

Dave